Month: November 2014

Service Companies Cut Drilling Fluid Costs without Losing Performance

November 26, 2014

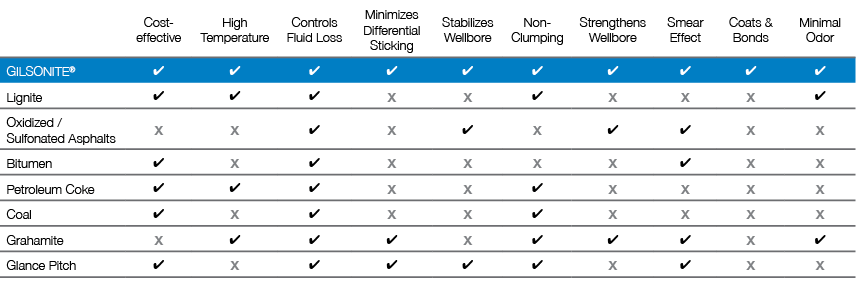

HOUSTON, TEXAS, November 26, 2014 – With industry-wide pressure to reduce expenditures, many service companies have found it cost-effective to reduce the total number of drilling fluid additives by incorporating a premium multi-purpose additive. American Gilsonite® uintaite provides a range of important benefits while also producing cost savings of more than 80%.

With its unique chemical properties and physical characteristics, Gilsonite® uintaite is scientifically proven to improve wellbore stability, plug micro-fractures, and bond and seal all types of formations. Gilsonite® is the only drilling fluid additive that provides all of these benefits:

- Controls fluid loss

- Stabilizes shales

- Prevents lost circulation

- Strengthens the wellbore

- Minimizes differential sticking

- Performs in oil- and water-based drilling muds

- Minimizes HSE risks

Significant cost advantages

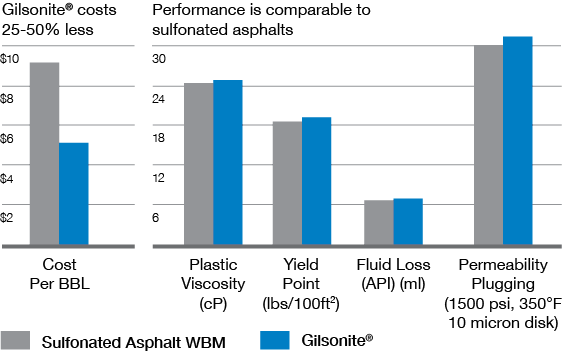

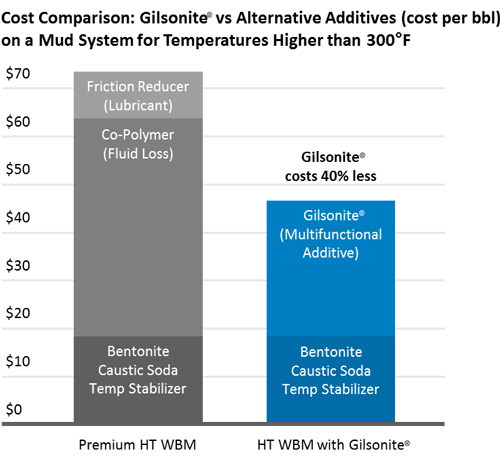

Compared to alternative products, Gilsonite® uintaite offers comparable or superior performance at a much lower cost.In water-based mud (WBM) applications, Gilsonite®’s performance compares favorably with sulfonated asphalts while costing 40% less.

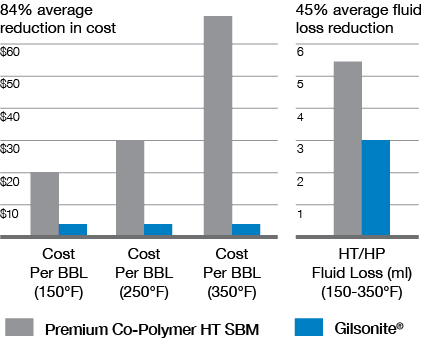

In HP/HT environments using synthetic-based mud (SBM), Gilsonite® uintaite provides a cost reduction of more than 80% compared to premium co-polymer, while the high softening point of Gilsonite® also results in a 45% reduction in fluid loss.

Proven performance advantages

Laboratory testing and years of field use have proven that Gilsonite® uintaite offers multiple performance benefits over alternative products.

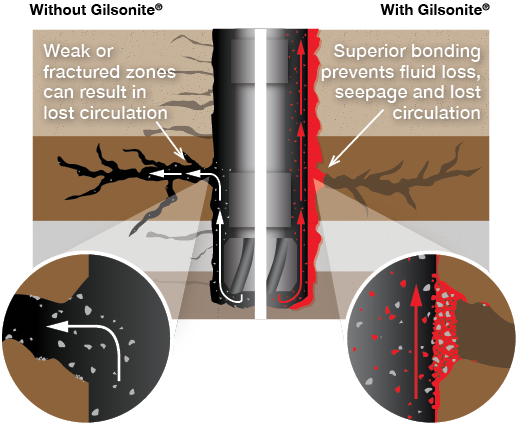

Unique properties control fluid loss and seepage

Gilsonite® uintaite has unique bonding and plugging properties that prevent formation damage. Gilsonite® forms a physical and chemical bond with permeable formations, creating an effective seal to prevent the passage of drilling fluid. By uniquely functioning as both a malleable and solid plugging agent, Gilsonite® controls fluid loss and seepage, prevents lost circulation, and protects reactive and low-reactive shale surfaces, even at elevated bottomhole temperatures.

Gilsonite® prevents lost circulation

Gilsonite® uintaite has been proven to bond and seal any type of formation. It prevents lost circulation when alone or in combination to enhance the performance of other lost circulation materials (LCM).

Proven to strengthen the wellbore

The demanding conditions of HP/HT wells, shales and underpressured zones require specialized drilling fluids and wellbore-strengthening techniques to preserve zonal isolation. Adding Gilsonite® uintaite strengthens the well by:

- Reducing pore pressure transmission and sealing micro-fractures in shale and low-porosity sands

- Keeping interbedding formations intact

- Developing effective filter cake

- Providing a “smear effect” that creates a continuous protective sealant along the wellbore wall

An effective additive to prevent differential sticking

Gilsonite® uintaite minimizes the occurrence, expense and downtime of stuck pipe and stuck logging tools by thoroughly sealing permeable formations – even in zones with a highly overbalanced pressure differential – and improving filter cake lubricity.

Multifunctional Gilsonite® reduces costs

Gilsonite® uintaite is a premium product that provides value from numerous benefits that improve drilling fluid performance as it also reduces overall costs by requiring fewer additives.

Recent Comments