New low-cost Gilsonite LCM improves pumping operations

November 4, 2021

New Gilsonite® LCM yields cost savings at purchase and during operations

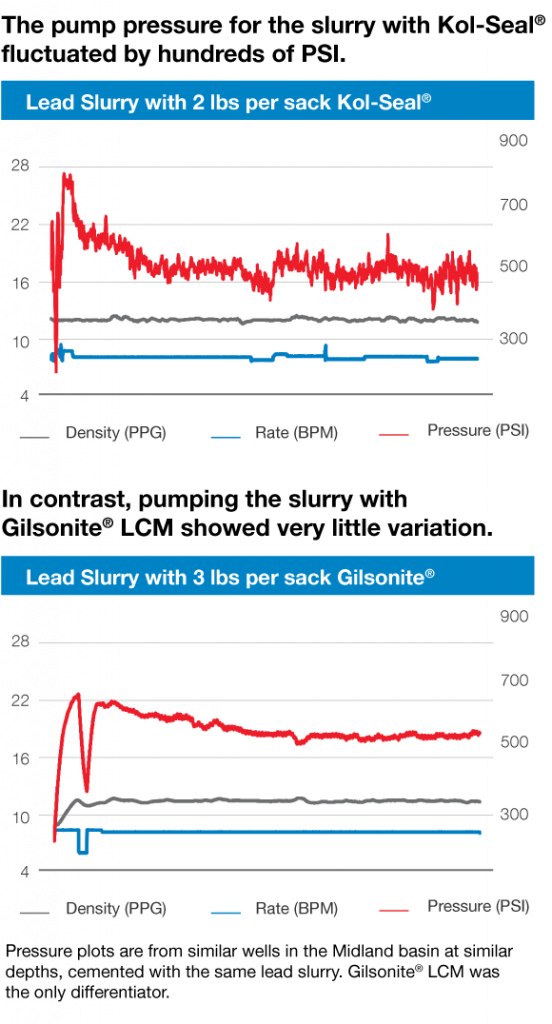

For wells drilled in the Midland Basin, West Texas Cementers adopted a new, competitively priced lost-circulation material (LCM) additive from American Gilsonite Company. West Texas Cementers (WTC) observed that the cement jobs with Gilsonite® LCM pumped smoother than jobs using Kol-Seal®, as evidenced by pressure charts.

Smoother pumping means less wear on pumps

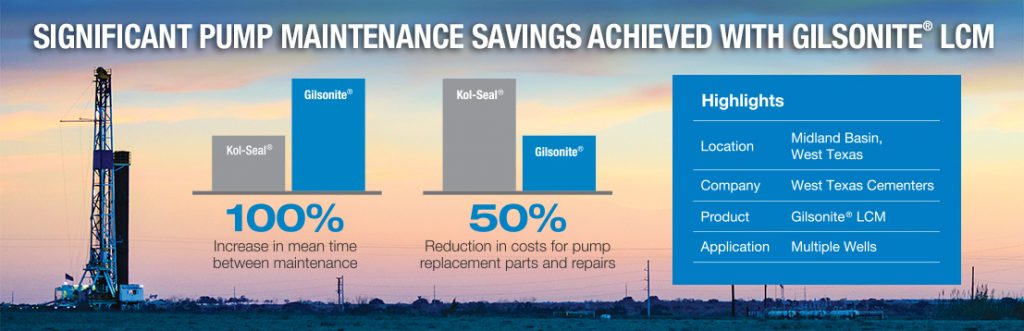

Further investigation revealed that using Gilsonite® LCM rather than Kol-Seal® doubled the operating time between pump maintenance resulting in a 50% reduction in pump replacement part costs and in the cost of labor for repairs.

Higher LCM concentration results in better lost circulation control

The erratic pressure behavior with Kol-Seal® in the slurry can be attributed to the material’s hardness and large particle sizes. “We were capped at two pounds per sack of Kol-Seal® previously due to how destructive it was on our valves and seats. We were able to increase the amount of LCM (from 2 lbs Kol-Seal® to 3 lbs Gilsonite®) so in general, more losses were mitigated,” noted Kevin Swikert WTC Engineer and Technical Manager.

Kevin concluded, “We have been pleased with the Gilsonite® LCM product. Our maintenance costs have been reduced and we are able to provide a better slurry to our clients.”

Contact us to learn more about how the world’s only true source of Gilsonite® can benefit your company.