Cementing

For more than 50 years, the industry has depended on Gilsonite® uintaite as a lost circulation material and a critical component for primary cementing operations in some of the world’s toughest drilling environments.

Adding Gilsonite® during cementing operations enhances the characteristics that are critical to effectively cementing the casing, isolating hydrocarbon formations and preventing annular gas flow.

With its unique physical and chemical properties, Gilsonite® uintaite provides a range of important benefits in slurry and set cement that are unmatched by any other single additive.

Cement slurry benefits

- Increases yield

- Reduces slurry weight

- Controls free water

- Lowers slurry water ratio

- Promotes favorable rheologies resulting in lower ECDs

- Prevents lost circulation

- Scours wellbore/enhances mud removal

Set cement benefits

- Maintains compressive strength, unlike coal or fly ash

- Increases flexibility

- Reduces cracking

- Heals microfissures

- Reduces permeability

- Strengthens bond to the formation and the casing

- Reduces environmental risk

- Assures zonal isolation

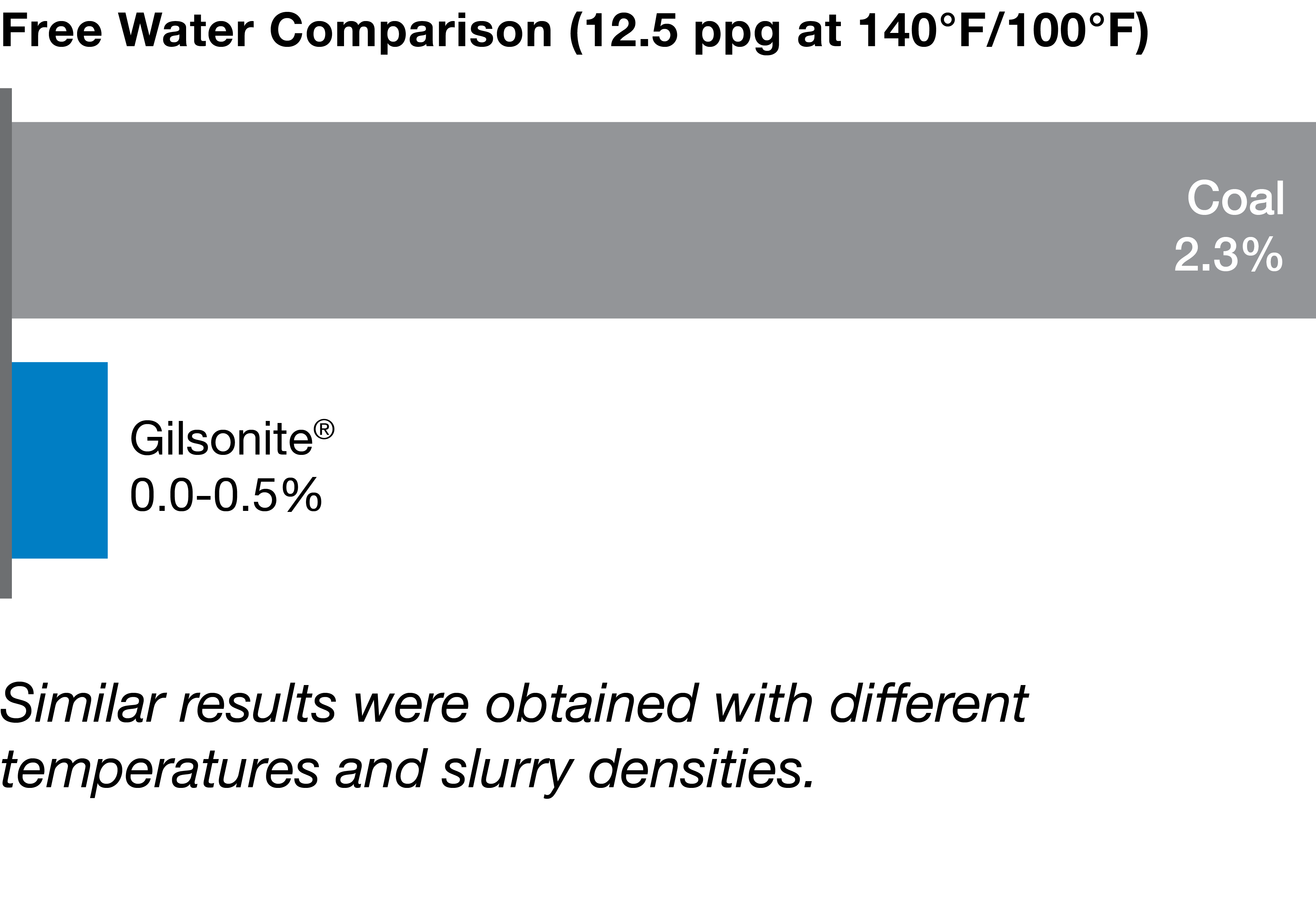

Gilsonite® eliminates the problems of free water

By controlling free water, Gilsonite® uintaite helps stabilize slurry and eliminates the need for – and cost of – additional free-water-control agents. As a lost circulation material, it also improves zonal isolation by preventing water channeling on the upper side of the wellbore.

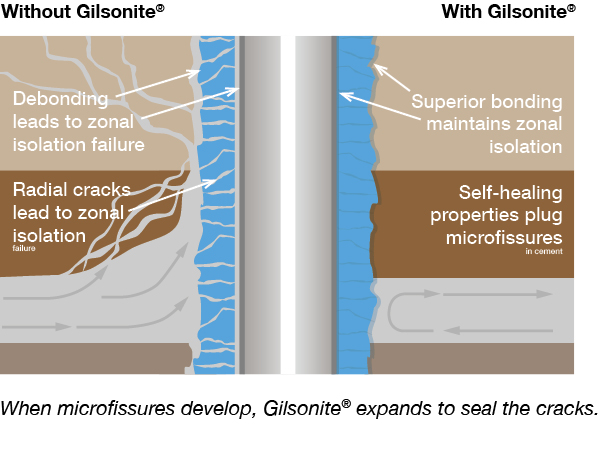

Self-healing properties help maintain zonal isolation

Gilsonite® uintaite is flexible, deformable, swellable, impermeable and non-porous. These characteristics give Gilsonite® self-healing properties that can plug induced microfissures in the cement sheath.

Cementing Product Overview

G-Bond Tech Sheet