Slurry with Gilsonite® increases yield and reduces cost

October 22, 2019

A West Texas O&G operator wanted to reduce slurry costs for its lightweight cement applications in the Permian Basin. The cementing company, West Texas Cementers (WTC), an independent cementing company in Odessa, Texas, replaced hollow beads with Gilsonite® uintaite. The result was a significant reduction in slurry costs.

WTC had typically used hollow beads as the lightweight additive in a 10.5 ppg cement system. “Our client asked us to provide a less expensive slurry with the same technical performance,” observed Kevin Swikert, WTC Engineer and Technology Manager. “We made a couple of additive substitutions in our cement system, with the primary change being to replace beads with Gilsonite® G-Bond.”

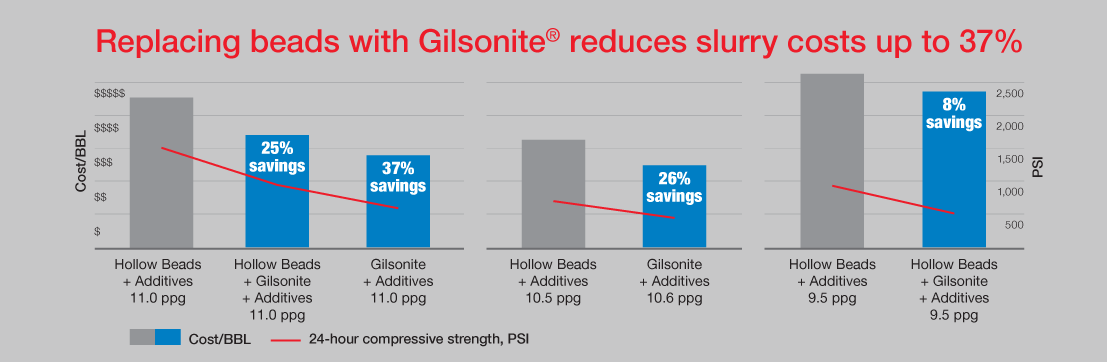

The revised 10.6 ppg cement system reduced slurry costs by 26% while still meeting all requirements defined by the operator and governing bodies in terms of thickening time, compressive strength development and cement fill behind the pipe.

Additional tests were conducted for offset wells in the Delaware Basin. Further testing showed that Gilsonite® G-Bond reduced slurry costs in a wide range of cement formulations, with up to 37% savings in an 11.0 ppg mixture.

“Other additives can change your design parameters. With Gilsonite® G-Bond, you don’t have to worry about that,” Swikert added. “In addition, Gilsonite® controls free water, lowers the slurry water ratio, prevents lost circulation, increases yield and mixes faster without foaming. I’m sold on Gilsonite® G-Bond as a cheaper option to glass beads. The other performance enhancements are an added benefit.”

Contact us to learn more about the world’s only true source of Gilsonite® and how Gilsonite® G-Bond can benefit your company.