Month: May 2015

Field Trials Reveal Gilsonite® Reduces Cost of Hollow Beads in Cementing

May 28, 2015

HOUSTON, TEXAS, May 28, 2015 – In the current oil and gas market, cutting costs has become a universal priority. Gilsonite® uintaite has proven to be an effective way to reduce the costs of using hollow beads without compromising the quality of a cementing job.

Hollow beads are frequently added to cement to reduce slurry density and increase compressive strength of set cement. While they are effective, hollow beads represent a significant expense. Field trials have shown that adding Gilsonite® uintaite to cement slurry while reducing the concentration of beads produces considerable cost savings.

Changing slurry formulations can reduce costs by 20%

The hollow beads commonly used as lightweight additives are up to seven times more expensive than Gilsonite® uintaite on a per-pound basis. Changing the formulation of slurry to incorporate Gilsonite® allows the use of fewer beads per sack of cement. Revised slurry designs provide the benefits of both the hollow beads and Gilsonite®, while total costs can be reduced by more than 20%.

Crushed beads compromise wellbore integrity

One disadvantage of hollow beads is that they can be crushed by downhole pressure. Even the wellsite mixing process can destroy beads. When beads don’t survive intact, the expected results are not delivered. Crushed beads can cause increased slurry density and viscosity, decreased volume, premature dehydration and increased equivalent circulating density. The intended cement design, along with wellbore integrity, could be compromised.

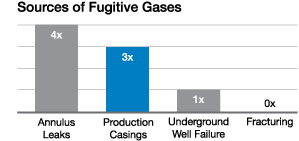

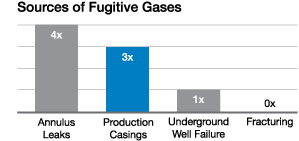

Wellbore integrity issues are primary cause of fugitive gases

The quality of the cementing job is critical to wellbore integrity and zonal isolation. According to the Proceedings of the National Academy of Sciences published September 15, 2014, wellbore integrity problems, not fracturing, were the predominant cause of fugitive gases.

Gilsonite® preserves wellbore integrity, zonal isolation

Gilsonite® uintaite is crushproof and maintains its chemical and physical properties under extreme conditions. Replacing hollow beads with Gilsonite® keeps slurry density low, supports compressive strength of set cement, and protects groundwater.

Gilsonite® in slurry:

- Increases yield

- Reduces slurry weight

- Controls free water

- Lowers slurry water ratio

- Promotes favorable rheologies resulting in lower ECDs

- Prevents lost circulation

- Scours wellbore/enhances mud removal

In set cement, Gilsonite®:

- Supports compressive strength development

- Increases flexibility

- Reduces cracking

- Heals microfissures

- Reduces permeability

- Strengthens bond to the formation and the casing

- Reduces groundwater contamination risk

- Complies with regulations

- Helps to prevent sustained casing pressure

Gilsonite® provides cost savings immediately and over the life of the well

With a cost significantly lower than hollow beads, Gilsonite® uintaite provides an operator with immediate savings. By assuring a high-quality cementing job and eliminating the expense of remedial cementing, Gilsonite® provides cost savings throughout the life of the well.

For more information, download our information sheet.

Recent Comments