Month: November 2021

Gilsonite® uintaite provides superior fluid loss control using less product

November 15, 2021

Difficult drilling conditions of highly deviated offshore wells present technical challenges

A global drilling fluids company operating in the Gulf of Mexico typically works on highly deviated wells with an average total depth of 5,000 meters (16,400 feet). Drilling challenges observed in these wells include salt domes and wellbore stability related to coal extrusions. Therefore, achieving tight control in fluid loss properties is of paramount importance in the drilling fluid design.

Alternative fluid loss additive required excessive amounts of product

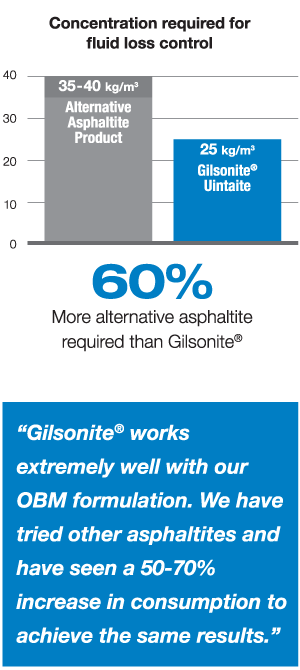

The company is using diesel-based fluids (OBM). In an attempt to reduce costs, the company switched to an alternative asphaltite product for fluid loss control. To achieve the needed effectiveness, the alternative product required a concentration of 35-40 kg/m3 (~9-11 ppb).

Gilsonite® provides fluid loss control with a significantly lower concentration

The drilling fluids company determined that a formulation with Gilsonite® uintaite consistently achieves the necessary fluid loss control in concentrations as low as 25 kg/m3 (~6 ppb). “Gilsonite® works extremely well with our OBM formulation. We have tried other asphaltites and have seen a 50-70% increase in consumption to achieve the same results,” said the Operations Support Manager of the company. Being able to purchase significantly lower quantities of Gilsonite® adds tremendous value for the client.

In addition, the client’s decision was reinforced by the assurance of American Gilsonite Company’s unmatched supply and ability to provide all the product required at the time needed.

New low-cost Gilsonite LCM improves pumping operations

November 4, 2021

New Gilsonite® LCM yields cost savings at purchase and during operations

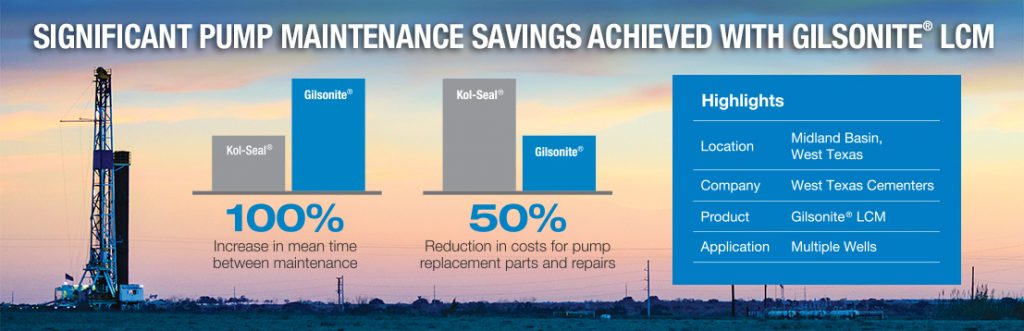

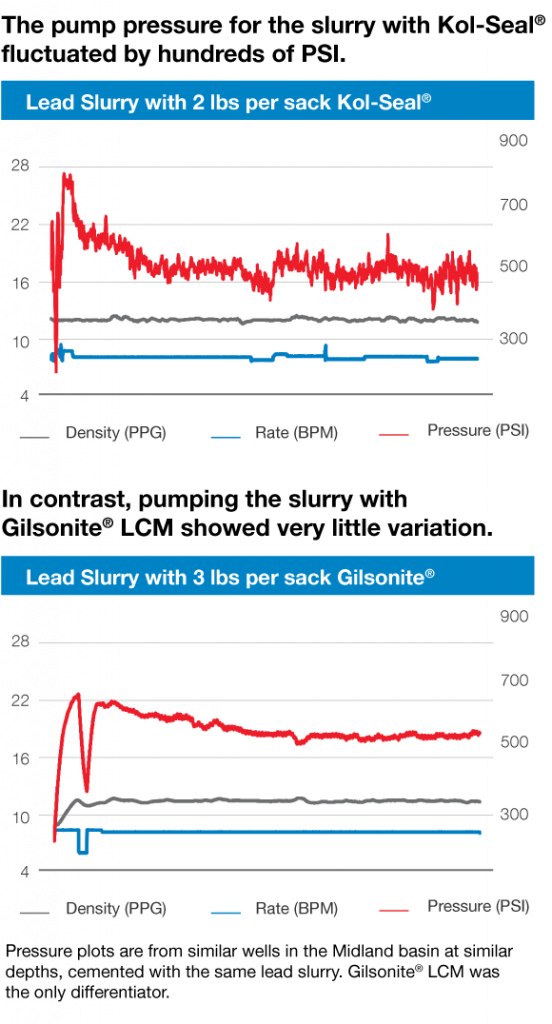

For wells drilled in the Midland Basin, West Texas Cementers adopted a new, competitively priced lost-circulation material (LCM) additive from American Gilsonite Company. West Texas Cementers (WTC) observed that the cement jobs with Gilsonite® LCM pumped smoother than jobs using Kol-Seal®, as evidenced by pressure charts.

Smoother pumping means less wear on pumps

Further investigation revealed that using Gilsonite® LCM rather than Kol-Seal® doubled the operating time between pump maintenance resulting in a 50% reduction in pump replacement part costs and in the cost of labor for repairs.

Higher LCM concentration results in better lost circulation control

The erratic pressure behavior with Kol-Seal® in the slurry can be attributed to the material’s hardness and large particle sizes. “We were capped at two pounds per sack of Kol-Seal® previously due to how destructive it was on our valves and seats. We were able to increase the amount of LCM (from 2 lbs Kol-Seal® to 3 lbs Gilsonite®) so in general, more losses were mitigated,” noted Kevin Swikert WTC Engineer and Technical Manager.

Kevin concluded, “We have been pleased with the Gilsonite® LCM product. Our maintenance costs have been reduced and we are able to provide a better slurry to our clients.”

Contact us to learn more about how the world’s only true source of Gilsonite® can benefit your company.

Recent Comments