Author: admin

New cost-effective Gilsonite® product provides crucial filtration control, maintains stable rheology

September 10, 2021

Ultra-deep wells and gypsum-salt formations present unique drilling challenges

The Sichuan Basin in southwest China is rich in ultra-deep natural gas and deep shale gas resources. Successful wells must be 7,000 to 8,000 meters (23,000 to 26,000 feet) deep. In addition, thick gypsum-salt rock formations present extreme engineering challenges, notably maintaining a stable rheological profile.

Other SBM additives fail to maintain stable fluid rheology

The client drilled with a synthetic-based mud (SBM) typically used in the region but was looking for a fluid loss control additive that would offer consistent performance while keeping emulsion strength and maintaining a stable rheological profile. Drilling fluid properties typically worsen when contaminated by highly pressurized brine in gypsum-salt formations. Therefore, consistent performance of additives is key.

New Gilsonite® product provides cost-effective filtration control, preserves other important fluid properties

The new Gilsonite® grade was used to replace other asphaltic additives that were less reliable and known to impact rheological values. A formulation with 8 ppb (pounds per barrel) of the new product provided adequate filtration control with no impact on rheology. In addition, it provided a cost-effective solution to improve the performance of the client’s SBM formulation. Gilsonite® uintaite is the only naturally occurring drilling fluid additive that prevents wellbore instability without affecting fluid rheology.

“Overall, we are pleased with the performance of the new Gilsonite® product, which is why we would like to promote it in China,” noted the client’s operations manager.

Contact us to learn more about how the world’s only true source of Gilsonite® can benefit your company.

American Gilsonite Company Mining Operations Celebrate 5-Year Safety Record

August 12, 2021

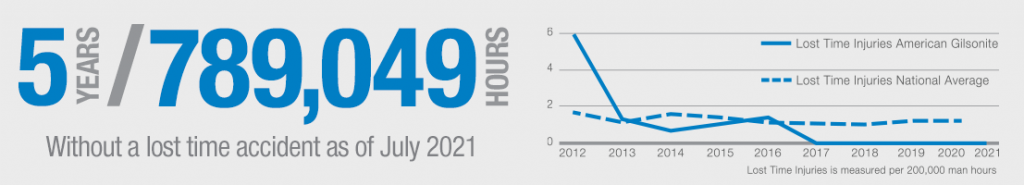

American Gilsonite Company CEO Craig Mueller and CFO Steve Granda recently traveled to our mining operations facility in Bonanza, Utah to congratulate COO Nick Lott and the Bonanza Operations team for their 5-year safety record.

Breaking 700,000 hours of no lost time accidents is a major achievement in any mining operation, and the company wanted to acknowledge the great work the Bonanza Operations team has done to make that possible.

American Gilsonite Company implemented an HSE safety program in 2015 that empowered employees to take an active role in improving their own safety, the safety of their coworkers and the safety of their environment. This resulted in the establishment of a world-class safety culture that has since been recognized for its accident-free operations, receiving the highest Safety Achievement Award from the Industrial Minerals Association-North America, as well as a Safety Award from the Utah Mining Association for the outstanding safety record.

To honor and celebrate the team’s accomplishments, American Gilsonite Company hosted a company steak picnic. The get-together included the Bonanza administrative office staff, the plant and warehouse team and the mining crew ‒ a rare gathering of all these groups in the same place at the same time! In addition to enjoying lunch together, employees were able to participate in an open forum Q&A session with Craig, Steve and Nick.

“We value our legacy and the people who helped create a first-rate culture of safety, quality and performance,” stated Craig Mueller. “Our focus on safety means that when you buy from American Gilsonite Company, you can be assured you’re supporting a company that values the safety of its workers and protection of the environment – and that you’re getting the quality and performance that comes exclusively from the world’s only true source of Gilsonite® uintaite.”

Contact us today to learn why American Gilsonite Company should be your trusted supplier and technical partner.

Congratulations Bonanza Operations team!

Office Staff

Plant and Warehouse Team

Mining Group

Outstanding safety record earns American Gilsonite Company the Utah Mining Association Safety Award

June 10, 2021

American Gilsonite Company has received the Utah Mining Association Safety Award for its accident-free operations. All recipients of the Safety Award were recognized at the 105th Annual Utah Mining Association Virtual Convention held on Tuesday, November 10, 2020.

The Utah Mining Association (UMA) annual safety awards program promotes mine safety and awareness and rewards the advancements of mine safety in the State of Utah. The program includes all UMA member companies, including service companies working in the industry.

American Gilsonite Company CEO Craig Mueller said, “American Gilsonite Company is very pleased to receive this award, and grateful for the recognition of our employees’ ongoing efforts to maintain a safe and healthy work environment. American Gilsonite Company now has over five years without a lost time injury, which we know is an outstanding achievement in the mining industry.”

American Gilsonite Company is the world’s only supplier of Gilsonite®, a naturally occurring hydrocarbon resin (uintaite). With a number of unique chemical properties and physical characteristics, Gilsonite has been used in a variety of applications and industries including oil and gas, foundries, asphalt, inks and paints. This unique mineral is only found in the Uintah Basin and we have been mining and processing Gilsonite continuously for over 100 years. We value our legacy and the people who have created a first-rate culture of safety, quality, and performance.

Rigorous trials prove genuine Gilsonite® uintaite will not remass

May 27, 2021

In laboratory testing and in client use, Gilsonite® uintaite, supplied by American Gilsonite Company, has proven its resistance to caking or remassing, even under high pressure, extreme temperatures and long-term storage. The chemical composition and refined purity of American Gilsonite® uintaite allow particles to remain loose and easy to mix, as opposed to competing products that tend to fuse together in storage and require re-milling in order to use them. For this reason, other asphaltites contain added fillers that reduce the purity of the product.

Gilsonite® uintaite showed no tendency to clump or cake, even after 4 weeks at constant high temperature and pressure

Gilsonite® uintaite showed no tendency to clump or cake, even after 4 weeks at constant high temperature and pressure

To test for any tendency to clump, cake or remass, American Gilsonite Company’s lab subjected a sample of Gilsonite® uintaite to constant heat of 60º C (140º F) for four weeks. At the conclusion of the test period, there was no appearance of any clumping or re-massing.

Additionally, the research and development lab at Gumpro Drilling Fluids conducted a carefully controlled test of Gilsonite® uintaite under high pressure as well as heat. Sacks of Gilsonite® uintaite were stacked in a 60º C (140º F) test oven as they would be in a warehouse, with the bottom bag bearing a load of 16 times its own weight. After eight days, the test concluded that there were no signs of caking.

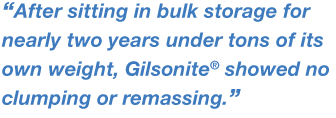

Gilsonite® uintaite remained granulated in storage for almost 2 years

In the field, Gilsonite® uintaite has been tested under extreme  conditions. In Odessa, Texas, a pumping company stored 37,000 pounds of Gilsonite® uintaite loose in a vertical silo for 22 months. Temperatures ranged from above 38º C (100º+ F) for months at a time to below freezing. “After sitting in bulk storage for nearly two years under tons of its own weight, Gilsonite® showed no clumping or remassing,” said a spokesperson for the pumping company. “There were no issues when unloading the silo, dry blending in the bulk plant or mixing at the wellsite.”

conditions. In Odessa, Texas, a pumping company stored 37,000 pounds of Gilsonite® uintaite loose in a vertical silo for 22 months. Temperatures ranged from above 38º C (100º+ F) for months at a time to below freezing. “After sitting in bulk storage for nearly two years under tons of its own weight, Gilsonite® showed no clumping or remassing,” said a spokesperson for the pumping company. “There were no issues when unloading the silo, dry blending in the bulk plant or mixing at the wellsite.”

Conclusion: Unlike inferior competing products, Gilsonite® uintaite will not remass

Competing products and counterfeit products posing as Gilsonite® uintaite have presented remassing issues as well as combustion issues when stored under similar conditions.

Results in the lab and in the field prove that Gilsonite® uintaite from American Gilsonite Company is the cost-effective, high-performance, multipurpose additive that will not cake or remass.

Contact us to learn more about how the world’s only true source of Gilsonite® can benefit your company.

Gilsonite® uintaite controls fluid loss without damaging the formation

April 14, 2021

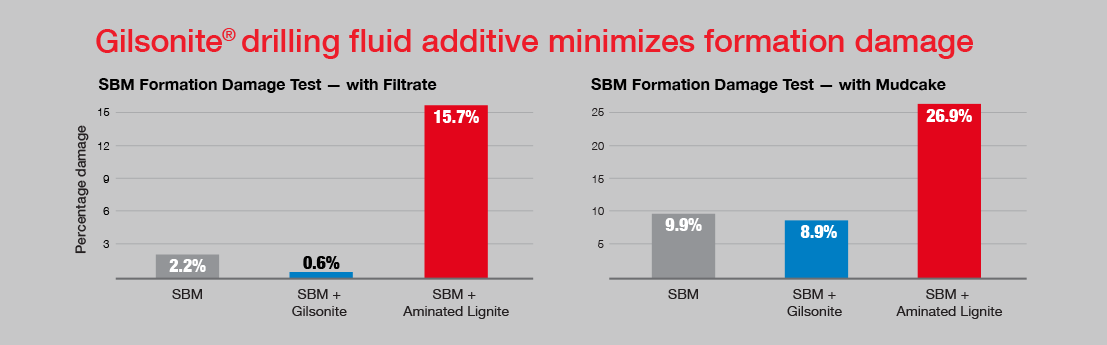

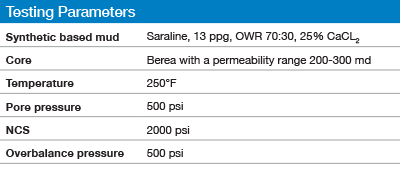

Gilsonite® reduces formation damage

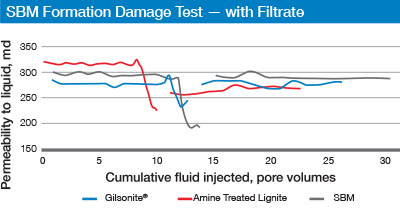

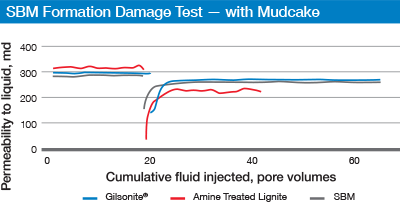

Lab tests show that Gilsonite® uintaite used as a fluid loss control additive in synthetic-based drilling mud (SBM) causes negligible formation damage. Third-party lab testing indicated that mud with Gilsonite® uintaite reduced damage to the hydrocarbon-bearing formation compared to synthetic-based mud alone.

Low-tier “black powder” additive damages the formation, reduces permeability

Testing shows that aminated lignite (a black powder additive) causes significant formation damage as measured by decreased return permeability.

Filtrate measurements indicated that Gilsonite® uintaite had negligible impact while mud filtrate containing the black powder additive showed a 15.7% decrease in return permeability. Measurements made without removing the mudcake again showed that Gilsonite® additive caused no formation damage while the black powder additive caused a 26.9% decrease in return permeability.

“It appears that Gilsonite® creates a good seal in the exposed formation, and therefore avoids causing formation damage,” stated Dario Montes, technical director for American Gilsonite Company.

Gilsonite® preserves production potential

Because Gilsonite® uintaite controls fluid loss while minimizing reservoir formation damage, it enables faster and safer drilling operations as it preserves the production potential and helps to optimize the value of an operator’s asset. Gilsonite® is the only drilling fluid additive that prevents lost circulation while increasing wellbore stability and minimizing differential sticking. Contact us today to learn more about the world’s only true source of Gilsonite® and how our high-performance drilling fluid additives can benefit your company.

Download case study

GILSONITE® uintaite classified GREEN in rigorous North Sea environmental standards

March 23, 2021

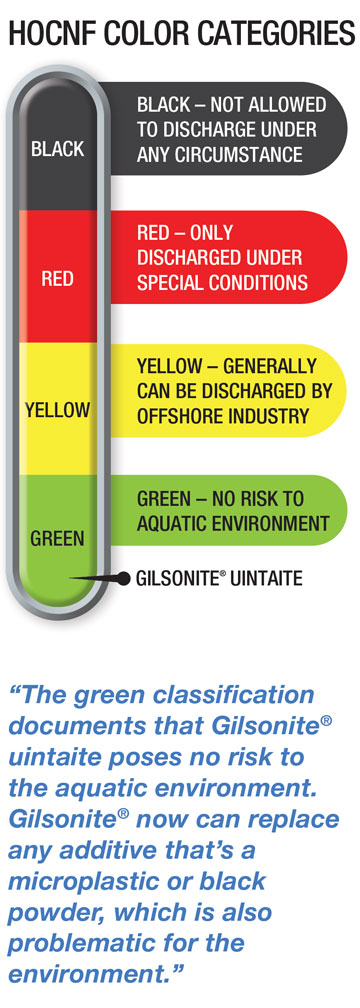

Gilsonite® uintaite has registered green under the Norwegian HOCNF Color Category System, demonstrating it is environmentally safe for use in the North Sea where there is potential for discharge into the marine environment.

HOCNF Color Category System, demonstrating it is environmentally safe for use in the North Sea where there is potential for discharge into the marine environment.

“This registration opens a whole new market since it comes at a time when our customers are looking for environmentally safe alternatives to microplastics, which up until a few years ago were deemed the environmentally safe option,” noted Ghery Sotomayor, Global Account Director at American Gilsonite Company. “Then it was determined that microplastics are in fact entering into marine organisms.”

The HOCNF (Harmonized Offshore Chemical Notification Format) is a mandatory reporting format in all countries that are members of the Convention for the Protection of the Marine Environment of the North-East Atlantic, or OSPAR. The HOCNF is increasingly used as the most appropriate method to document and control offshore chemicals’ environmental properties.

“The Green classification documents that Gilsonite® uintaite poses no risk to the aquatic environment,” Sotomayer added. “Gilsonite® now can replace any additive that’s a microplastic or black powder, which is also problematic for the environment.”

The HOCNF classification is important beyond the North Sea because many other areas with offshore and deepwater oil and gas operations have adopted the strict North Sea environmental standards.

The OSPAR Convention is the mechanism by which 15 governments and the European Union cooperate to protect the marine environment of the Northeast Atlantic. Member nations include Belgium, Denmark, Finland, France, Germany, Iceland, Ireland, Luxembourg, The Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and the United Kingdom.

Gilsonite® uintaite is a naturally occurring hydrocarbon resin that is non-toxic, non-carcinogenic, non-mutagenic and has been classified as safe by the EPA for use in the Gulf of Mexico. With a unique blend of strength, flexibility, bonding and high-temperature capability, Gilsonite® has proven to increase performance in cementing and drilling fluids for over 60 years. The American Gilsonite Company mines in the Uinta Basin of Northeastern Utah are the only true source of Gilsonite®.

Accident-free operations earn American Gilsonite highest safety award

September 30, 2020

While presenting the prestigious award, IMA-NA Chairman Doug Smith explained, “The Safety Achievement Award recognizes the best reportable injury rate for an individual IMA-NA member company by size category for the preceding calendar year. We’re pleased to recognize IMA-NA member companies that have compiled excellent safety records and who serve as examples for other companies.” American Gilsonite Company posted the highest safety rating in the Medium Category.

Noting the importance of the award, Smith added that the safety recognition awards program is run in cooperation with the U.S. Department of Labor’s Mine Safety and Health Administration (MSHA). “The safety performance of these IMA members is truly inspiring,” said IMA-NA President Mark Ellis. He took special note of the performance of American Gilsonite Company, emphasizing, “Medium Category Honoree American Gilsonite Company had zero injuries while working 178,957 employee hours, for an injury rate of 0.00 per 200,000 employee work hours. To put that in perspective, the injury rate for all metal and nonmetal mines in 2019 was 1.72.”

Accepting the award for American Gilsonite Company were Chief Operating Officer Nick Lott and Director HS&E Mike Wilhite. Lott said, “American Gilsonite Company is honored to receive this award, and the employees are grateful for this recognition for their daily efforts towards creating a safe and healthy environment.”

Accepting the award for American Gilsonite Company were Chief Operating Officer Nick Lott and Director HS&E Mike Wilhite. Lott said, “American Gilsonite Company is honored to receive this award, and the employees are grateful for this recognition for their daily efforts towards creating a safe and healthy environment.”

Wilhite said, “All of us at American Gilsonite in Bonanza, Utah, and in Houston, Texas, appreciate this award. I would like to thank IMA-NA for recognizing our men and women for their dedication to working safely.”

Further explaining the company’s record of operational safety, Lott added, “Although this is a recognition of 2019, American Gilsonite Company has achieved over four years without a lost time injury. Mike Wilhite and the other supervisors at the operations have worked hard to create a culture that focuses on collaboration and frequent participation with the employees.”

“Not only have these efforts resulted in a good safety record, but they have also provided a positive work experience for the employees that resulted in strong leadership and an improved operational efficiency,” Lott continued. “We are very appreciative of the culture that has been created and look forward to continued improvements towards the health and safety of our employees.”

Asphalt costs reduced 13%+ and performance improved with Gilsonite®

March 13, 2020

STUDY SHOWS GILSONITE® OFFERS SUPERIOR MASTIC ASPHALT PERFORMANCE AT LOWER ADDITIVE CONCENTRATIONS

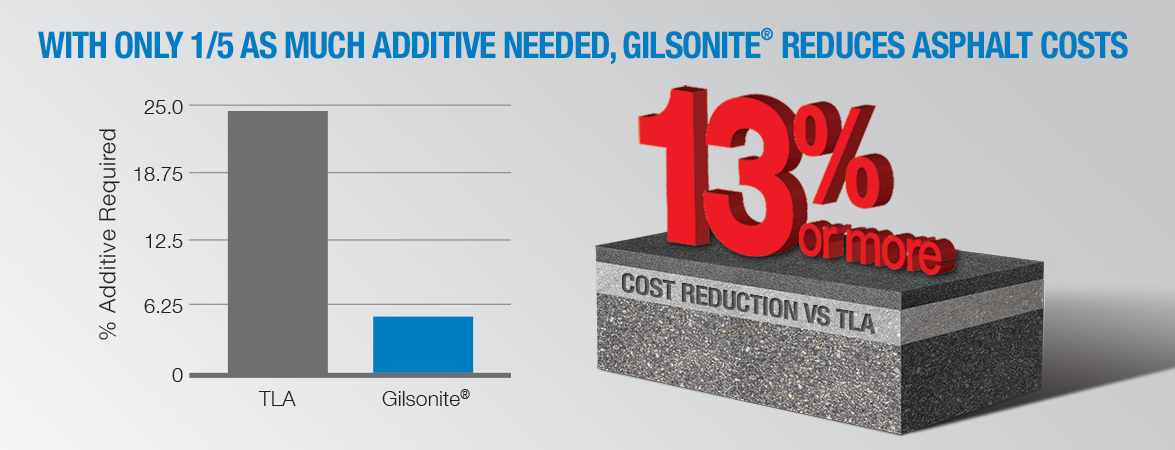

An independent study was conducted to determine how the physical and chemical properties of Gilsonite® uintaite performed compared to Trinidad Lake Asphalt (TLA). The study compared a typical mastic asphalt bitumen modified with 24.4% TLA and formulations of bitumen modified with Gilsonite® at significantly lower concentrations of 5%.

Gilsonite® provides clear performance advantages over TLA

Compared to the TLA mixture, the samples modified with Gilsonite® uintaite provided greater resistance to rutting, cracking and deformation while also providing the ability to withstand colder temperatures without breaking.

Compared to the TLA mixture, the samples modified with Gilsonite® uintaite provided greater resistance to rutting, cracking and deformation while also providing the ability to withstand colder temperatures without breaking.

- Improved Fatigue Resistance

Gilsonitc® enhances viscosity and reduces fatigue and cracking - Improved Cracking Resistance

Gilsonite® provides superior cold temperature performance - Improved Rutting Resistance

Gilsonite® increases softening point to resist rutting and moisture

Less material = less energy required and significantly lower costs

A formulation with 24.4% TLA uses five times the additive as a mixture using 5% Gilsonite®. This reduction in additives can result in a 13% or more decrease in materials costs. When combined with lower energy costs required for blending, Gilsonite® provides significant savings.

The findings clearly demonstrate that Gilsonite®-modified binders make stronger, longer lasting roads, and that Gilsonite® uintaite is a superior alternative to the industry’s current mastic asphalt standard.

Contact us to learn more about the world’s only true source of Gilsonite® and how it can improve the performance and reduce the costs of your asphalt projects.

RELATED RESOURCES

American Gilsonite continues expanding customer base in the Middle East at ADIPEC 2019

December 20, 2019

American Gilsonite once again had a presence at one of the world’s largest and most influential oil and gas conferences – the 2019 Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC). This year’s four-day event, held in November 2019, had a record-breaking attendance of more than 155,000 industry professionals from around the globe.

and most influential oil and gas conferences – the 2019 Abu Dhabi International Petroleum Exhibition and Conference (ADIPEC). This year’s four-day event, held in November 2019, had a record-breaking attendance of more than 155,000 industry professionals from around the globe.

Alongside other companies that help shape the future of oil and gas landscape, American Gilsonite leveraged the opportunity at the conference to showcase the superior advantages of true Gilsonite® and provide information on the strength, flexibility, extreme light weight and environmental safety of Gilsonite® uintaite.

In addition to participating in the conference, the AGC Eastern Hemisphere  Marketing and Sales Team hosted an ADIPEC After Party at the prestigious Azura Lounge at The St. Regis in the Abu Dhabi Corniche district. Attendees enjoyed cocktails and hors d’oeuvres, and had the opportunity to learn more about the unmatched benefits of Gilsonite® in cementing and drilling fluids in virtually any downhole environment worldwide, as well as discuss their specific product and business needs with the AGC team.

Marketing and Sales Team hosted an ADIPEC After Party at the prestigious Azura Lounge at The St. Regis in the Abu Dhabi Corniche district. Attendees enjoyed cocktails and hors d’oeuvres, and had the opportunity to learn more about the unmatched benefits of Gilsonite® in cementing and drilling fluids in virtually any downhole environment worldwide, as well as discuss their specific product and business needs with the AGC team.

Craig Mueller – VP and Chief Commercial Officer; Ghery Sotomayor – Senior Account Manager, Drilling Fluids; Ashley Barnes – Senior Marketing & Sales Analyst; and Rozalina Bojey – Marketing Coordinator for the Middle East and Far East markets represented American Gilsonite at the conference and after party. The AGC team was impressed with attendance at both events and appreciated the meaningful interactions with regional customers and potential business partners.

“This year’s participation at ADIPEC, and the customer social event we had the pleasure to host, were invigorating. As AGC moves closer to our goal of becoming a major local player in the Middle East, we continue to be amazed by the level of engagement and energy we see from the industry in this part of the world,” said Craig Mueller, VP and Chief Commercial Officer.

“This year’s participation at ADIPEC, and the customer social event we had the pleasure to host, were invigorating. As AGC moves closer to our goal of becoming a major local player in the Middle East, we continue to be amazed by the level of engagement and energy we see from the industry in this part of the world,” said Craig Mueller, VP and Chief Commercial Officer.![]()

Contact us to learn more about the world’s only true source of Gilsonite and how it can benefit your company.

Slurry with Gilsonite® increases yield and reduces cost

October 22, 2019

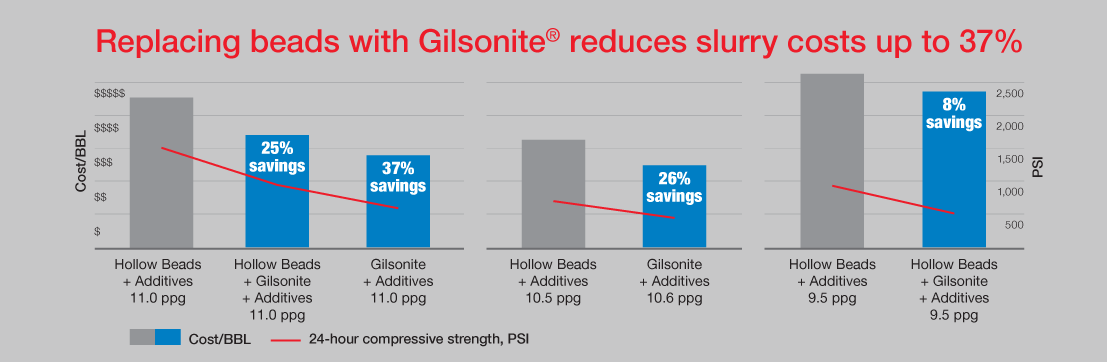

A West Texas O&G operator wanted to reduce slurry costs for its lightweight cement applications in the Permian Basin. The cementing company, West Texas Cementers (WTC), an independent cementing company in Odessa, Texas, replaced hollow beads with Gilsonite® uintaite. The result was a significant reduction in slurry costs.

WTC had typically used hollow beads as the lightweight additive in a 10.5 ppg cement system. “Our client asked us to provide a less expensive slurry with the same technical performance,” observed Kevin Swikert, WTC Engineer and Technology Manager. “We made a couple of additive substitutions in our cement system, with the primary change being to replace beads with Gilsonite® G-Bond.”

The revised 10.6 ppg cement system reduced slurry costs by 26% while still meeting all requirements defined by the operator and governing bodies in terms of thickening time, compressive strength development and cement fill behind the pipe.

Additional tests were conducted for offset wells in the Delaware Basin. Further testing showed that Gilsonite® G-Bond reduced slurry costs in a wide range of cement formulations, with up to 37% savings in an 11.0 ppg mixture.

“Other additives can change your design parameters. With Gilsonite® G-Bond, you don’t have to worry about that,” Swikert added. “In addition, Gilsonite® controls free water, lowers the slurry water ratio, prevents lost circulation, increases yield and mixes faster without foaming. I’m sold on Gilsonite® G-Bond as a cheaper option to glass beads. The other performance enhancements are an added benefit.”

Contact us to learn more about the world’s only true source of Gilsonite® and how Gilsonite® G-Bond can benefit your company.

Recent Comments