Author: admin

American Gilsonite Company Appoints New Eastern Hemisphere Sales and Operations Director

August 16, 2023

American Gilsonite Company is pleased to have Dave Clark, who formerly worked on special projects, step into the role of Director, Eastern Hemisphere Sales and Operations, effective March 2023. Dave is responsible for our commercial strategy, business development, advancement of technologies for customer-focused products, and leadership of our eastern hemisphere sales and operations team. He will work closely with President and CEO, Craig Mueller, to develop strategies that continue to drive the company’s long-term international commercial success.

American Gilsonite Company is pleased to have Dave Clark, who formerly worked on special projects, step into the role of Director, Eastern Hemisphere Sales and Operations, effective March 2023. Dave is responsible for our commercial strategy, business development, advancement of technologies for customer-focused products, and leadership of our eastern hemisphere sales and operations team. He will work closely with President and CEO, Craig Mueller, to develop strategies that continue to drive the company’s long-term international commercial success.

“Key to our company’s corporate strategy is the growth of our Eastern Hemisphere product lines, both oilfield and industrial,” noted Craig Mueller, President and CEO. “It’s critical that we have a strong management presence in that part of the world. Dave brings a unique skill set to our company, having years of operational and commercial experience in locations including Asia Pacific, Middle East, and Northern Europe.”

“I’m very excited to accept this new role and continue developing the long-term success and brand of American Gilsonite Company in a strategically important part of the world which has tremendous growth potential,” said Dave Clark.

Dave is a seasoned executive with more than 30 years of extensive international commercial and leadership experience working in business development, marketing and sales, and operations management roles in the energy and chemical industries.

Team members honored with service awards at summer BBQ

August 9, 2023

American Gilsonite Company employees and their families recently enjoyed a day of fun in the sun at our 2nd Annual Summer Employee BBQ & Cornament in Jensen, UT. We enjoyed great food and weather while playing cornhole and recognizing our employees and their families for their dedication to service with American Gilsonite Company.

Managers joined in on the fun sliding down the water slides!

General Manager Craig Brown presented this year’s service awards.

Others recognized but not in attendance included Mark Christopherson (20 years), Wilmer Moreno (15 years), Corey Webb (10 years) and Alan Evans (10 years).

2nd Annual American Gilsonite Company Cornhole Tournament

Cornament winners Glenn Murray and Justin Spence took home custom American Gilsonite Company Cornhole Boards!

New multifunctional product improves drilling performance in water-based systems

March 29, 2023

The first in a new line of multifunctional WBM products optimizes operational results and costs

American Gilsonite Company approached the Rockies operations group of a drilling fluids provider with the concept of running a field trial with a unique water-based additive. The service provider agreed to run the product in

an intermediate section (4,000 to 11,000 ft depth) of their client’s well.

The expectation was for improved operational results at a reduced cost.

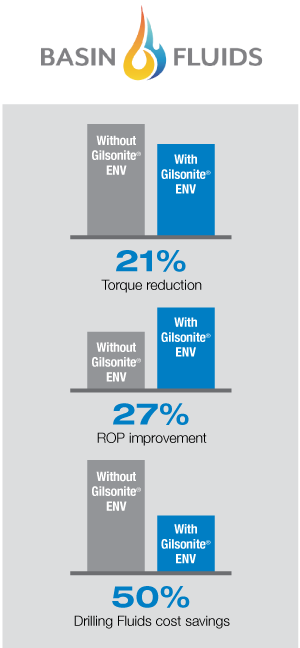

Addition of Gilsonite® ENV allowed for an overall reduced concentration of mud additives

The service provider switched to a water-based mud formulation (9.8 ppg, 3% KCl) using engineered Gilsonite® ENV. After a successful first field trial yielded intermediate section mud cost savings of 36%, the decision was made to run a second trial. In the second trial, total fluid additive volumes were reduced, including sulfonated asphalt and XCD, resulting in intermediate section mud cost reduction of 50%.

Gilsonite® ENV reduces costs, yields additional operational benefits

In addition to the intermediate sections mud cost reduction, the Gilsonite® ENV mud formulation produced these superior results:

- Casing run time was reduced by 3.5 hours

- Rate of penetration (ROP) improved by 27%

- Torque reduced by 21%

- Excellent wellbore integrity due to better shale control

Contact us to learn more about how the world’s only true source of Gilsonite® can benefit your company.

SPE Paper: Uintaite is Approved for Use in Drilling Operations in Sensitive Marine Environments

January 26, 2023

Over the last thirty years the oil and gas industry has implemented high environmental standards to reduce its impact on the environment. As drilling and completion fluids services are one of the main components in drilling operations, North Sea environmental regulations require every chemical compound in the drilling fluid formulation to be evaluated before approval for use.

This paper outlines the chemical composition and testing of Gilsonite® uintaite, with the following conclusions:

- Low thermal maturity and nil aromatic content within uintaite matrix is one of the unique features that defines why uintaite is not harmful in environmental tests.

- Uintaite does not interfere with thermal maturity biomarkers.

- Uintaite possesses chemical and geochemical characteristics that make it a non-harmful natural material, due to its very low content of dangerous compounds such as sulfur or aromatics rings.

- Low Pow results for bioaccumulation pointed out that uintaite will not bioaccumulate, because it is not soluble either in water or n-Octanol.

- Molecular weight of uintaite is significantly higher than 7 kDalton and does not penetrate through skin.

- Uintaite is an inert natural material for marine species according to EPA and OSPAR guidelines for environment protection. It can be used in the GoM or in the North Sea as a drilling fluid additive with no negative impacts to the environment.

- Uintaite has negligible or innocuous effect in the reservoir.

- Environmental tests results and rock-fluid interaction determine that uintaite is a safe additive for marine ecosystems.

Ghery Sotomayor of American Gilsonite Company shared the high points of this paper with peers at the ADIPEC 2022 Exhibition and Conference – demonstrating that Gilsonite is safe and effective in sensitive marine environment drilling operations.

To learn more, download a copy of the SPE paper from the OnePetro library.

Contact us to learn more about how the world’s only true source of Gilsonite® uintaite can benefit your company.

Gilsonite® G-Bond provides exceptional slurry for Western U.S. wells

December 1, 2022

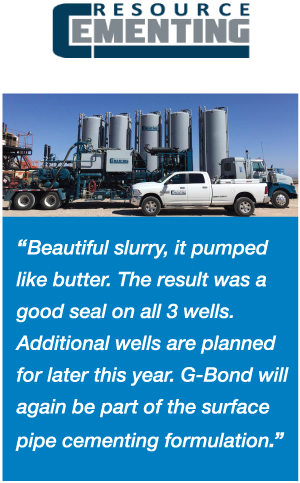

Western U.S. operators face circulation loss, wellbore isolation issues

Wells drilled in a Western U.S. state commonly encounter formations that result in lost circulation during primary surface pipe cementing. Resource Cementing company was pumping slurry in a well with 1,025 feet of 9.625˝ casing set in a 12.5˝ open hole with an 11.0 ppg lightweight cement. Controlling lost circulation and providing good compressive strength were primary concerns.

Gilsonite® G-Bond provides circulation-loss control

with greater compressive strength

Resource Cementing selected Gilsonite® G-Bond as an additive. G-Bond rapidly disperses in cement mix water, so high concentrations can be used to obtain a low slurry density without jeopardizing wellsite mixing or pumping. G-Bond lowered both the hydrostatic pressure and the equivalent circulation density (ECD). Cement returned to the surface on three out of three wells.

G-Bond achieves strong seal and isolation

The cement slurry exhibited some thixotropic properties. Wells treated with G-Bond demonstrated a strong seal and wellbore isolation. Only one well showed post-job backside gas, at a trace level well within acceptable limits. The Operations Support Manager of Resource Cementing stated that using Gilsonite® G-Bond helped create “a beautiful slurry – it pumped like butter. The result was a good seal on all three wells. Additional wells are planned for later this year. G-Bond will again be part of the surface pipe cementing formulation.”

Contact us to learn more about how the world’s only true source of Gilsonite® can benefit your company.

American Gilsonite Company strengthens management team, announces new general manager

August 17, 2022

Craig Brown, MBA, P.E. joins AGC to lead all aspects of the company’s operations.

American Gilsonite Company, Inc. (“AGC”), the world’s only supplier of Gilsonite® uintaite, is pleased to announce the addition of Craig Brown as General Manager, effective June 6, 2022. Mr. Brown is responsible for AGC’s operations including reserves management, mining and mine development, processing, and distribution.

Craig will work closely with AGC’s executive team, as well as local management, to develop and execute strategies that will continue to drive the company’s long-term commercial success.

Mr. Brown has more than 10 years of experience in the mining industry, with extensive knowledge in production planning and execution, project and capital management, as well as proven leadership in both his professional and military career. He joins AGC from Genesis Alkali, where he most recently served as production manager.

“We are pleased to have Mr. Brown join AGC’s management team. His skillset, education, practical operational experience, and management style will allow our Utah-based workforce to realize its full potential,” noted Craig Mueller, President and CEO of AGC.

“I am very humbled and excited to be joining a company with a proud history of more than 130 years of industry leadership and innovation. I am committed to a continued focus on quality management systems and product improvement to help drive growth for the company,” said Craig Brown, General Manager of AGC.

Mr. Brown is a veteran of the United States Army. He earned a Bachelor of Science degree from University of Utah in Mining Engineering, is a certified Professional Engineer, and went on to earn his Executive MBA from David Eccles School of Business at the University of Utah.

Bonanza mine employees golf for a great community cause

May 27, 2022

American Gilsonite Company employees from our Bonanza mining facility were excited to take part in this year’s Uintah County Sheriff’s Office annual charity golf tournament benefiting the local Special Olympics. The event was held on Friday, May 6 at Dinaland Golf Course in Vernal, UT. Two teams of four employees from American Gilsonite Company joined in the fun. The Bonanza team also sponsored a hole with a “closest to the pin game” for a prize.

Founded in 1968, the Special Olympics strives to create a better world by fostering the acceptance and inclusion of all people. Through the power of sports, people with intellectual disabilities discover new strengths and abilities, skills and success. Athletes find joy, confidence and fulfillment ─ on the playing field and in life. They also inspire people in their communities and elsewhere to open their hearts to a wider world of human talents and potential.

The Northeastern Utah Special Olympics are held every year in May. Local law enforcement and emergency response agencies make the torch run a special event by escorting the Olympians down Highway 40 with lights flashing and sirens wailing! It’s always a great time for the whole community. American Gilsonite Company is proud to support this important local cause.

Rigorous ISO 9001 Certification Awarded to American Gilsonite Company for Mining and Processing

December 13, 2021

American Gilsonite Company has been recognized with ISO 9001:2015 Certification for the mining and processing of uintaite ore. ISO 9001 is the most widely recognized quality management standard in the world.

To achieve ISO 9001:2015 certification, American Gilsonite Company underwent an extensive audit of its quality management system, management review, product conformity control and documentation. Verisys Registrars performed the audit, and American Gilsonite Company received certification in September 2021.

“By achieving this level of certification, we continue to demonstrate our ability and desire to incorporate a quality management system effectively and efficiently while continuously improving our products and services as well as our internal processes,” said Craig Mueller, President and CEO of American Gilsonite. “Although AGC has been supplying uintaite for over 100 years, this certification gives our customers added assurance of the quality and consistent supply of our product.”

Mueller added that the international certification reflects American Gilsonite’s commitment to customers emphasized in the Company Quality Policy:

American Gilsonite Company is committed to consistent, high-performing products and reliable service by always understanding and meeting customers’ requirements and expectations. We are also committed to a culture that fosters integrity, a sense of responsibility, and an awareness of and compliance with all other applicable governing requirements.

We strive to continually improve our products and services by regularly measuring, monitoring, and reporting our performance against established quality objectives.

“We would also like to take this opportunity to extend our sincere thanks to our customers and suppliers for their continued commitment and loyalty. American Gilsonite Company will always strive to exceed their high expectations,” concluded Mueller. “With our goals focused on quality assurance and innovative production, we look forward to bringing the business to new heights in the months and years to come.”

Contact us today to learn why American Gilsonite Company should be your trusted supplier and technical partner.

Gilsonite® uintaite provides superior fluid loss control using less product

November 15, 2021

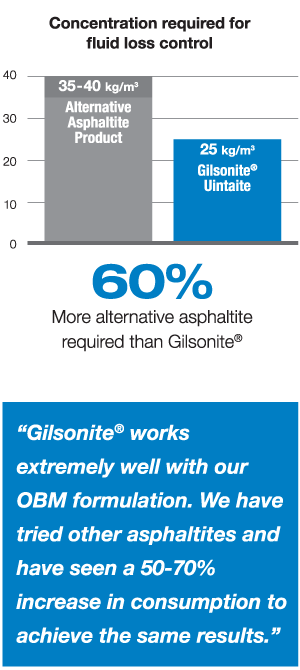

Difficult drilling conditions of highly deviated offshore wells present technical challenges

A global drilling fluids company operating in the Gulf of Mexico typically works on highly deviated wells with an average total depth of 5,000 meters (16,400 feet). Drilling challenges observed in these wells include salt domes and wellbore stability related to coal extrusions. Therefore, achieving tight control in fluid loss properties is of paramount importance in the drilling fluid design.

Alternative fluid loss additive required excessive amounts of product

The company is using diesel-based fluids (OBM). In an attempt to reduce costs, the company switched to an alternative asphaltite product for fluid loss control. To achieve the needed effectiveness, the alternative product required a concentration of 35-40 kg/m3 (~9-11 ppb).

Gilsonite® provides fluid loss control with a significantly lower concentration

The drilling fluids company determined that a formulation with Gilsonite® uintaite consistently achieves the necessary fluid loss control in concentrations as low as 25 kg/m3 (~6 ppb). “Gilsonite® works extremely well with our OBM formulation. We have tried other asphaltites and have seen a 50-70% increase in consumption to achieve the same results,” said the Operations Support Manager of the company. Being able to purchase significantly lower quantities of Gilsonite® adds tremendous value for the client.

In addition, the client’s decision was reinforced by the assurance of American Gilsonite Company’s unmatched supply and ability to provide all the product required at the time needed.

New low-cost Gilsonite LCM improves pumping operations

November 4, 2021

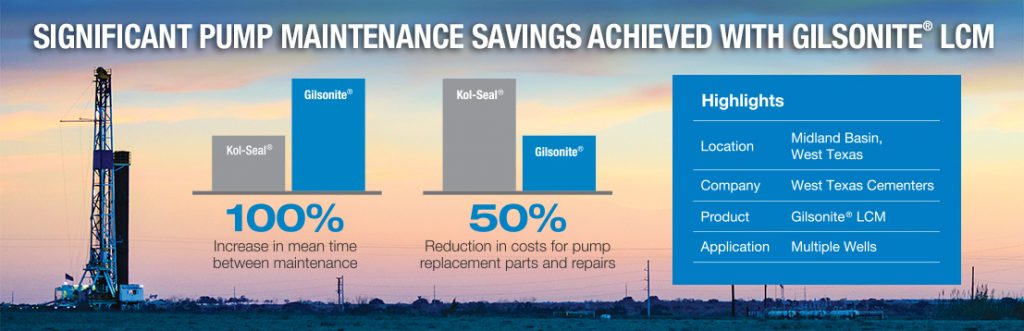

New Gilsonite® LCM yields cost savings at purchase and during operations

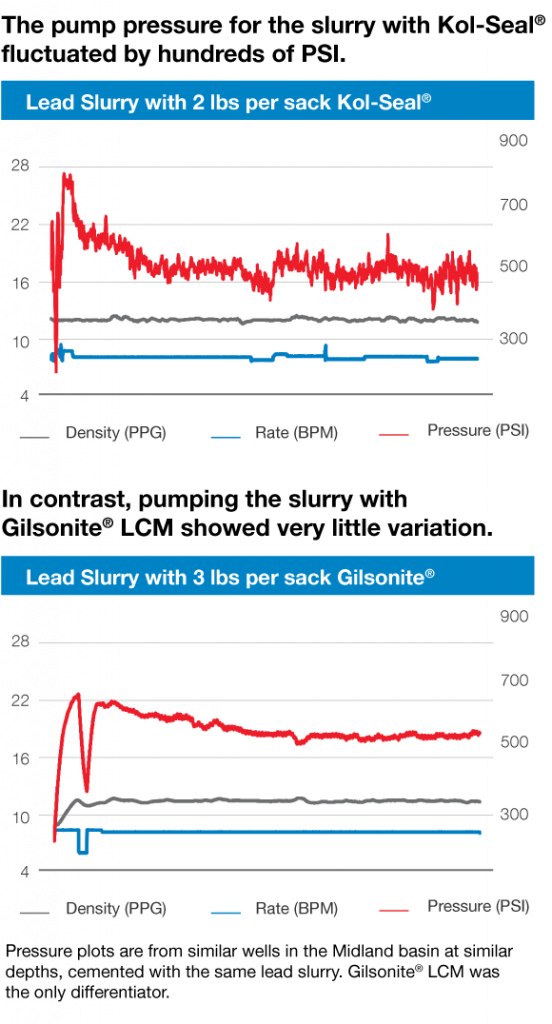

For wells drilled in the Midland Basin, West Texas Cementers adopted a new, competitively priced lost-circulation material (LCM) additive from American Gilsonite Company. West Texas Cementers (WTC) observed that the cement jobs with Gilsonite® LCM pumped smoother than jobs using Kol-Seal®, as evidenced by pressure charts.

Smoother pumping means less wear on pumps

Further investigation revealed that using Gilsonite® LCM rather than Kol-Seal® doubled the operating time between pump maintenance resulting in a 50% reduction in pump replacement part costs and in the cost of labor for repairs.

Higher LCM concentration results in better lost circulation control

The erratic pressure behavior with Kol-Seal® in the slurry can be attributed to the material’s hardness and large particle sizes. “We were capped at two pounds per sack of Kol-Seal® previously due to how destructive it was on our valves and seats. We were able to increase the amount of LCM (from 2 lbs Kol-Seal® to 3 lbs Gilsonite®) so in general, more losses were mitigated,” noted Kevin Swikert WTC Engineer and Technical Manager.

Kevin concluded, “We have been pleased with the Gilsonite® LCM product. Our maintenance costs have been reduced and we are able to provide a better slurry to our clients.”

Contact us to learn more about how the world’s only true source of Gilsonite® can benefit your company.

Recent Comments