Author: admin

American Gilsonite Offers New G-Bond Cementing Additive for Improved Mixability at Higher Concentrations

April 12, 2016

American Gilsonite Company now offers Gilsonite® G-Bond to deliver even more performance in formulations with higher concentrations.

Mixes easily without foaming – saves time, space and money

Gilsonite® G-Bond is traditional cementing grade Gilsonite® uintaite with a surfactant coating. It is free-flowing and easily disperses in water for rapid wellsite mixing – even at high concentrations. Its unique characteristics eliminate the time and expense of adding wetting agents and defoamers, as well as the time, space and cost of using a batch mixer.

Now you can further improve the physical and chemical properties of your slurry and set cement by using higher concentrations of Gilsonite®.

- Enhance cement bonding

- Prevent sustained casing pressure

- Improve zonal isolation

- Eliminate need for blenders or batch mixers onsite

- Prevent pump cavitation

- Eliminate need for wetting and defoaming agents

Instantly enhance cement properties without changing your formulation

With its superior hydrophilic characteristics, Gilsonite® G-Bond readily mixes at concentrations approaching 30% or even 40% without requiring any additional changes to the slurry formulation. It is ultra-lightweight, highly dispersible and can be mixed on the fly without requiring any blenders or batch mixers.

For more information, download the technical information sheet.

Innovation Center Opens in American Gilsonite’s New Corporate Headquarters

February 18, 2016

American Gilsonite Company hosted an open house to unveil our high-tech Innovation Center located inside the new corporate headquarters in Houston. Customers, vendors and other business partners were on hand to get a first hand look at the new Innovation Center. This advanced facility is equipped and staffed to conduct an array of critical testing and analyses that enables more precise and consistent formulations, improved product performance, shortened lead times and more cost-effective solutions.

Innovation Center capabilities

In addition to developing industry-leading products, our Innovation Center provides unmatched client support to solve complex drilling fluids and cementing challenges.

- Product development

- Drilling fluid system development

- Cement slurry design support

- Real-time client technical support

- Client collaboration on formulation design

- Quality assurance

“Our Innovation Center brings together the expertise and technology to create solutions that reduce costs while optimizing performance,” stated David Gallagher, President and CEO for American Gilsonite Company.

“We collaborate with our clients to formulate additives for both drilling fluids and cement, optimized for specific downhole environments. By testing and fine-tuning formulations prior to actual use, we assure that our clients receive the highest-performing additives and most cost-effective solutions in the timeliest manner,” Gallagher added.

For more information about the Innovation Center, download our brochure.

David G. Gallagher Named President and Chief Executive Officer of American Gilsonite Company

January 29, 2016

Oil & gas veteran to lead major producer of additives for drilling fluids, cementing, asphalt, inks, and foundry applications

American Gilsonite Company, Inc. (“AGC”), the world’s major supplier of Gilsonite® uintaite, today announced the appointment of David G. Gallagher to the position of President and Chief Executive Officer, effective immediately. Mr. Gallagher has more than 30 years of experience in the oil and gas service sector, having served with Schlumberger, CARBO Ceramics, and Baker Hughes in engineering, operations, product development, and executive management roles. He joined AGC in 2013 as Senior Vice President, Commercial Operations.

American Gilsonite Company, Inc. (“AGC”), the world’s major supplier of Gilsonite® uintaite, today announced the appointment of David G. Gallagher to the position of President and Chief Executive Officer, effective immediately. Mr. Gallagher has more than 30 years of experience in the oil and gas service sector, having served with Schlumberger, CARBO Ceramics, and Baker Hughes in engineering, operations, product development, and executive management roles. He joined AGC in 2013 as Senior Vice President, Commercial Operations.

“We brought David aboard in order to revitalize our commercial efforts, with the intent that he would eventually serve a larger role,” said Willson Ropp, Chairman of the Board of AGC, “His strong leadership, ability to attract top-tier talent, and business acumen have greatly contributed to the success of the company in a number of important new areas.”

Mr. Gallagher commented, “I am humbled and blessed to take the helm of a company with a proud history of more than 125 years of industry leadership and innovation. The dedication and professionalism of the team across the entire organization is inspiring. Our product, Gilsonite®, is a naturally occurring asphaltite that serves as an effective binder and strengthener in a broad range of end uses. For decades, this ‘magical mineral’ has been a key additive for drilling fluids and cementing in the oil and gas sector as well as for asphalt, inks and paints, and foundry.

“Reflecting our heightened focus on bringing cost-effective products to market quickly, we recently opened an Innovation Center in Houston. In this advanced testing and evaluation facility, our clients have been actively collaborating with us to develop high-performance products for specific applications – all of which helps us to demonstrate the significant value of Gilsonite® products in the marketplace,” Mr. Gallagher concluded.

Mr. Ropp added, “We want to thank Ted Stevens for his leadership and dedication to American Gilsonite Company over the last 17 years. Ted is a proven executive who led the efforts to modernize our operations and safely protect our workers and the environment. We wish him well in his retirement.”

Mr. Gallagher earned a Bachelor of Engineering degree from the University of New Mexico.

About American Gilsonite Company

American Gilsonite Company (AGC) is the world’s primary miner and processor of uintaite, a naturally occurring hydrocarbon similar in appearance to hard asphalt believed to be found in commercial quantities only in the Uinta Basin in northeastern Utah. AGC’s extensive mining operations in the area assure customers of a secure supply of the pure grade uintaite that AGC markets under its registered trademark name “Gilsonite®.” Because of its unique chemical and physical properties, Gilsonite® uintaite has been used in more than 160 products. The company sells its products to customers in four primary markets: (i) oil and gas, (ii) inks and paints, (iii) foundry, and (iv) asphalt. AGC is headquartered in Houston, Texas, with mining facilities based in Bonanza, Utah. American Gilsonite Company is a privately held portfolio company of Palladium Equity Partners III, L.P.

| Investor Relations Contact Peter Hill Kekst and Company 212-521-4800 peter.hill@kekst.com |

Media Relations Contact Paige Donnell Paige PR 832-566-6503 paige@paigepr.com |

Announcing the Opening of Our Permian Basin Supply Center in Midland, Texas

January 4, 2016

ANNOUNCING THE OPENING OF OUR PERMIAN BASIN SUPPLY CENTER IN MIDLAND, TEXAS

American Gilsonite Company is pleased to announce the opening of our Permian Basin Supply Center in Midland, Texas. Located in America’s second largest oil and gas producing region, our new Supply Center is strategically situated to expand our customer base as well as to better serve the needs of our existing customers.

A full range of Gilsonite® uintaite products for both cementing and drilling fluids (both OBM and WBM) are now available for same day pickup or delivery. Plus, customers have the option of buying less-than-truckload quantities – especially important to smaller independents who can now realize the benefits of Gilsonite® in their projects without the need to maintain a large inventory of the product.

“With the help of our distribution partner, Agri-Empresa, we’ve significantly reduced delivery time to our customers in the Permian Basin area,” says Stanley Jepsen, Vice President – Drilling Fluids for American Gilsonite Company. “This makes it faster and easier than ever to take advantage of Gilsonite®’s cost-effective strength, flexibility, bonding and high-temperature capability.”

For more information, download our information sheet.

To place an order from the Permian Basin Supply Center, contact our distribution partner, Agri-Empresa:

832-974-4387.

Scientific study proves benefits of Gilsonite® uintaite in asphalt pavement

November 30, 2015

A 2015 study by the Western Regional Superpave Center at the Department of Civil and Environmental Engineering of the University of Nevada, Reno, proved that Gilsonite®-modified binders significantly extend the useful life of asphalt pavement. This is good news for agencies looking to reduce the long-term costs of asphalt pavement maintenance.

Findings from comprehensive testing demonstrated that Gilsonite®-modified binders showed significant improvement in:

- Tensile strength – The addition of Gilsonite® uintaite significantly increased both the unconditioned and moisture-conditioned tensile strength.

- Compressive strength – Gilsonite®-modified binders showed significant improvement in compressive strength.

- Rutting strength – Gilsonite®-modified binders significantly increased projected pavement life. In all but one case, adding Gilsonite® yielded a ten-fold increase.

- Fatigue resistance – The projected pavement life is 1.5 to 5 times longer with the Gilsonite®-modified binders.

Gilsonite® improves performance and reduces cost

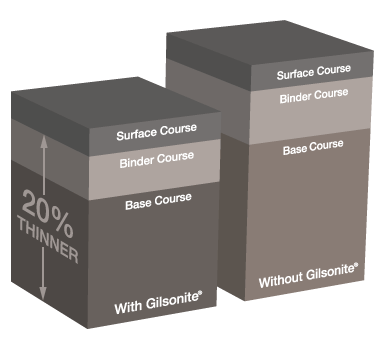

Industry reports of Gilsonite®-modified asphalt lasting more than twice as long as unmodified mixtures are common. In addition, the high modulus provided by Gilsonite® uintaite allows the base and binder courses to be up to 20% thinner while still providing the same level of performance, enabling the use of less material. Gilsonite® can also act as a lower-cost, performance-enhancing extender in a mixture including SBS polymers.

By significantly extending the useful life of asphalt pavement and allowing a reduction in the amount of paving material required, Gilsonite® uintaite has proven to offer substantial cost effectiveness.

For more information about improving asphalt with Gilsonite®, contact us today.

Introducing Our New and Expanded Line of High Temperature Drilling Mud Additives

August 10, 2015

After extensive R&D and a multimillion dollar investment in mining capacity, American Gilsonite Company now has an expanded range of HT drilling mud additives ready for immediate delivery.

Gilsonite® HT performs in the most extreme conditions

- Enhances mud properties for HP/HT environments

- High softening point extends thermal life 10% or more

- Prevents lost circulation and minimizes differential sticking

- Proven to be safe, natural and effective

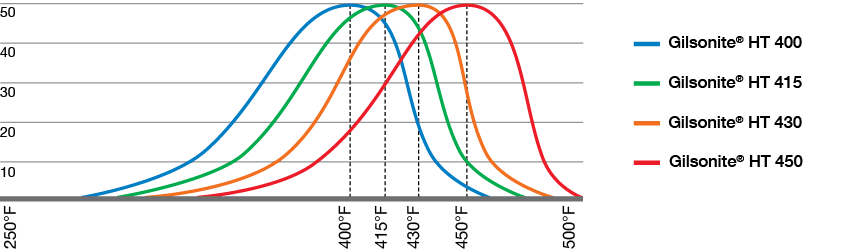

A new range of higher softening points (% cumulative particle)

Gilsonite® HT performs at temperatures as high as 500ºF.

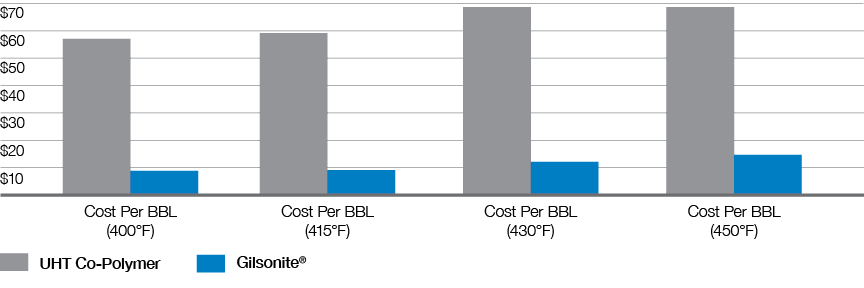

Gilsonite® HT reduces costs more than 60% vs. premium polymers

Our full line of high-temp products:

- NEW PRODUCT: Gilsonite® HT450 (softening point >450º)

- Gilsonite® HT430 (softening point >430º)

- Gilsonite® HT415 (softening point >415º)

- NEW PRODUCT:Gilsonite® HT400 (softening point >400º)

- Available for WBM, OBM and SBM

Contact us today for pricing and delivery.

Download the product brochure in English | Spanish | Chinese

Field Trials Reveal Gilsonite® Reduces Cost of Hollow Beads in Cementing

May 28, 2015

HOUSTON, TEXAS, May 28, 2015 – In the current oil and gas market, cutting costs has become a universal priority. Gilsonite® uintaite has proven to be an effective way to reduce the costs of using hollow beads without compromising the quality of a cementing job.

Hollow beads are frequently added to cement to reduce slurry density and increase compressive strength of set cement. While they are effective, hollow beads represent a significant expense. Field trials have shown that adding Gilsonite® uintaite to cement slurry while reducing the concentration of beads produces considerable cost savings.

Changing slurry formulations can reduce costs by 20%

The hollow beads commonly used as lightweight additives are up to seven times more expensive than Gilsonite® uintaite on a per-pound basis. Changing the formulation of slurry to incorporate Gilsonite® allows the use of fewer beads per sack of cement. Revised slurry designs provide the benefits of both the hollow beads and Gilsonite®, while total costs can be reduced by more than 20%.

Crushed beads compromise wellbore integrity

One disadvantage of hollow beads is that they can be crushed by downhole pressure. Even the wellsite mixing process can destroy beads. When beads don’t survive intact, the expected results are not delivered. Crushed beads can cause increased slurry density and viscosity, decreased volume, premature dehydration and increased equivalent circulating density. The intended cement design, along with wellbore integrity, could be compromised.

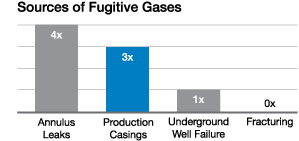

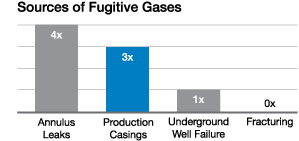

Wellbore integrity issues are primary cause of fugitive gases

The quality of the cementing job is critical to wellbore integrity and zonal isolation. According to the Proceedings of the National Academy of Sciences published September 15, 2014, wellbore integrity problems, not fracturing, were the predominant cause of fugitive gases.

Gilsonite® preserves wellbore integrity, zonal isolation

Gilsonite® uintaite is crushproof and maintains its chemical and physical properties under extreme conditions. Replacing hollow beads with Gilsonite® keeps slurry density low, supports compressive strength of set cement, and protects groundwater.

Gilsonite® in slurry:

- Increases yield

- Reduces slurry weight

- Controls free water

- Lowers slurry water ratio

- Promotes favorable rheologies resulting in lower ECDs

- Prevents lost circulation

- Scours wellbore/enhances mud removal

In set cement, Gilsonite®:

- Supports compressive strength development

- Increases flexibility

- Reduces cracking

- Heals microfissures

- Reduces permeability

- Strengthens bond to the formation and the casing

- Reduces groundwater contamination risk

- Complies with regulations

- Helps to prevent sustained casing pressure

Gilsonite® provides cost savings immediately and over the life of the well

With a cost significantly lower than hollow beads, Gilsonite® uintaite provides an operator with immediate savings. By assuring a high-quality cementing job and eliminating the expense of remedial cementing, Gilsonite® provides cost savings throughout the life of the well.

For more information, download our information sheet.

Service Companies Cut Drilling Fluid Costs without Losing Performance

November 26, 2014

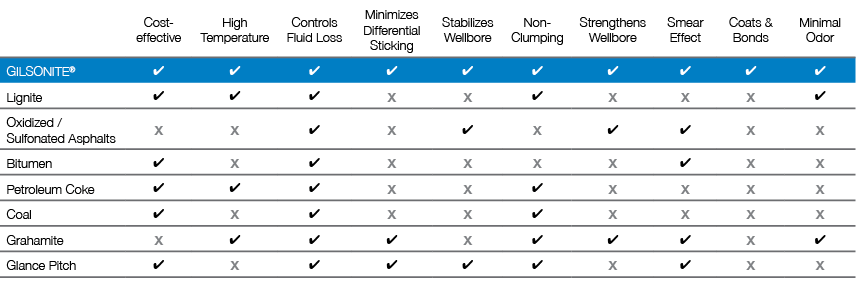

HOUSTON, TEXAS, November 26, 2014 – With industry-wide pressure to reduce expenditures, many service companies have found it cost-effective to reduce the total number of drilling fluid additives by incorporating a premium multi-purpose additive. American Gilsonite® uintaite provides a range of important benefits while also producing cost savings of more than 80%.

With its unique chemical properties and physical characteristics, Gilsonite® uintaite is scientifically proven to improve wellbore stability, plug micro-fractures, and bond and seal all types of formations. Gilsonite® is the only drilling fluid additive that provides all of these benefits:

- Controls fluid loss

- Stabilizes shales

- Prevents lost circulation

- Strengthens the wellbore

- Minimizes differential sticking

- Performs in oil- and water-based drilling muds

- Minimizes HSE risks

Significant cost advantages

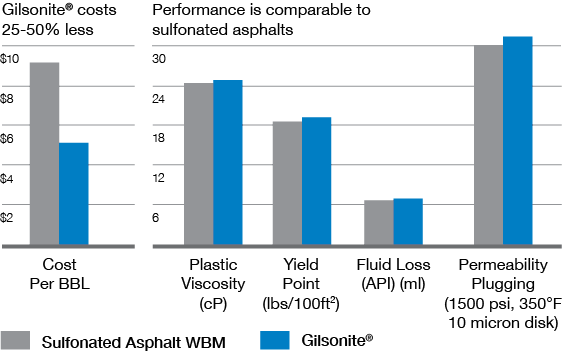

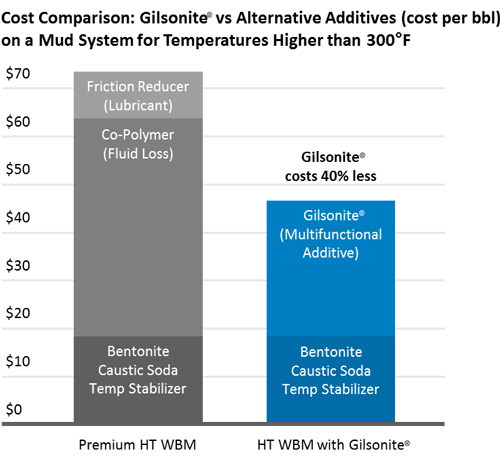

Compared to alternative products, Gilsonite® uintaite offers comparable or superior performance at a much lower cost.In water-based mud (WBM) applications, Gilsonite®’s performance compares favorably with sulfonated asphalts while costing 40% less.

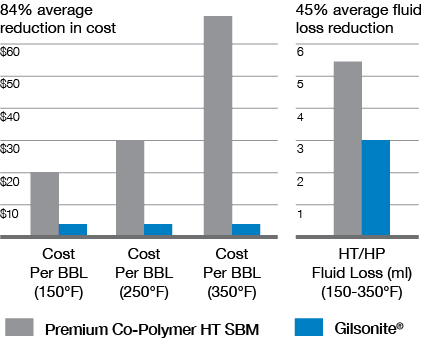

In HP/HT environments using synthetic-based mud (SBM), Gilsonite® uintaite provides a cost reduction of more than 80% compared to premium co-polymer, while the high softening point of Gilsonite® also results in a 45% reduction in fluid loss.

Proven performance advantages

Laboratory testing and years of field use have proven that Gilsonite® uintaite offers multiple performance benefits over alternative products.

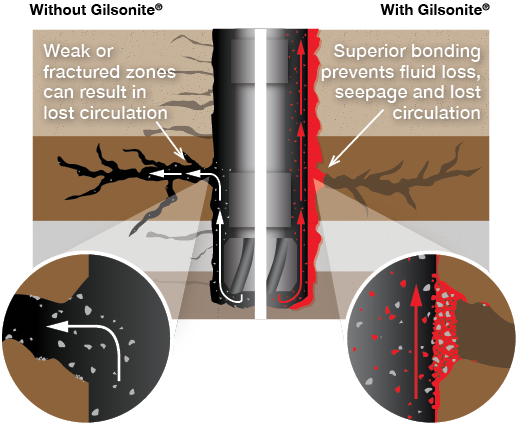

Unique properties control fluid loss and seepage

Gilsonite® uintaite has unique bonding and plugging properties that prevent formation damage. Gilsonite® forms a physical and chemical bond with permeable formations, creating an effective seal to prevent the passage of drilling fluid. By uniquely functioning as both a malleable and solid plugging agent, Gilsonite® controls fluid loss and seepage, prevents lost circulation, and protects reactive and low-reactive shale surfaces, even at elevated bottomhole temperatures.

Gilsonite® prevents lost circulation

Gilsonite® uintaite has been proven to bond and seal any type of formation. It prevents lost circulation when alone or in combination to enhance the performance of other lost circulation materials (LCM).

Proven to strengthen the wellbore

The demanding conditions of HP/HT wells, shales and underpressured zones require specialized drilling fluids and wellbore-strengthening techniques to preserve zonal isolation. Adding Gilsonite® uintaite strengthens the well by:

- Reducing pore pressure transmission and sealing micro-fractures in shale and low-porosity sands

- Keeping interbedding formations intact

- Developing effective filter cake

- Providing a “smear effect” that creates a continuous protective sealant along the wellbore wall

An effective additive to prevent differential sticking

Gilsonite® uintaite minimizes the occurrence, expense and downtime of stuck pipe and stuck logging tools by thoroughly sealing permeable formations – even in zones with a highly overbalanced pressure differential – and improving filter cake lubricity.

Multifunctional Gilsonite® reduces costs

Gilsonite® uintaite is a premium product that provides value from numerous benefits that improve drilling fluid performance as it also reduces overall costs by requiring fewer additives.

American Gilsonite Company Names David Gallagher as Senior Vice President

November 11, 2013

HOUSTON, Texas, November 11/PRNewswire-FirstCall/ — American Gilsonite Company, Inc. (“American Gilsonite”, or “AGC”), the world’s primary supplier of Gilsonite® uintaite, today announced it has appointed David G. Gallagher as Senior Vice President, Commercial Operations, effective immediately. Mr. Gallagher has more than 30 years of experience in the oilfield service industry, holding executive level positions at leading firms such as Schlumberger, Carbo Ceramics and Baker Hughes.

President and Chief Executive Officer Ted Stevens said, “We are excited to have someone with David’s comprehensive experience and extensive knowledge in the oil and gas industry, including both conventional and unconventional resource development, to lead the continued expansion of our global business. His successful career has included assignments in engineering, operations, marketing and sales, and executive management, both domestically and internationally. David has substantial experience in developing client focused solutions that will be central to our growth strategy, and under his direction, we anticipate further penetration in our core global markets, more focused direction in our R&D efforts and a further expansion of our product portfolio.”

Gallagher earned a Bachelor’s of Engineering degree from The University of New Mexico.

About American Gilsonite Company

AGC operates as an industrial minerals company and is the world’s primary miner and processor of uintaite, a variety of asphaltite, a specialty hydrocarbon which AGC markets to industrial customers under its registered trademark name “Gilsonite®“. Gilsonite® uintaite is a glossy, black, solid naturally occurring hydrocarbon similar in appearance to hard asphalt and is believed to be found in commercial quantities only in the Uinta Basin in northeastern Utah. Because of its unique chemical and physical properties, Gilsonite® has been used in more than 160 products. The company sells its products to customers in four primary markets: (i) oil and gas, (ii) inks and paints, (iii) foundry and (iv) asphalt. AGC is headquartered in Bonanza, Utah. AGC is a privately held, portfolio company of Palladium Equity Partners III, L.P.

Press Contact

Peter Hill

Kekst and Company

212-521-4800

peter.hill@kekst.com

American Gilsonite Completes Houston Office Expansion

July 23, 2013

HOUSTON, TEXAS – July 23, 2013 – American Gilsonite Company, Inc. (“American Gilsonite”, or “AGC”), the world’s primary supplier of Gilsonite® uintaite, announced the completion of its Houston office expansion. Major growth in the energy sector prompted the company to establish a significant presence in Houston to better serve the expanding customer base.

“As a strategic supplier to the world largest oil and gas service companies, we felt that it was imperative to expand our commitment to this crucial end market,” said Ted Stevens, President and Chief Executive Officer of American Gilsonite. “We are excited about this important milestone and look forward to the continued expansion of our Houston team.”

After spending more than 30 years in both operations and sales with M-I Swaco, Vice President of Sales and Marketing Bill Dobbs, joined American Gilsonite two years ago to lead the build-out of the AGC Houston team. “Establishing a robust presence in Houston is essential to providing excellent customer service to our core oilfield customers”, said Mr. Dobbs. “With the additions of Technical Director Dario Montes from NOV and M-I Swaco, and Sales Manager for Oilfield Products Matt Garner from Baker Hughes, we have the technical and commercial foundation to provide value to our customers.”

The Houston office is located near the Galleria at 1717 St. James Place, Suite 600.

About American Gilsonite Company. (www.americangilsonite.com)

American Gilsonite is the world’s primary miner and processor of Gilsonite® uintaite, a naturally occurring hydrocarbon resin used as a premium performance additive in oilfield and specialty industrial applications. AGC and its predecessor companies have been mining Gilsonite® in Eastern Utah since 1888.

Recent Comments